Turbine flow transmitter itself does not have the display function, only will flow with two wire system 4-20 ma current signal in the form of far transfer out, outside the + 24 VDC power supply, remote transmission distance is 500 m.

By the reason of current signal is not susceptible to interference.And current source internal resistance infinity, does not affect the accuracy of circuit conductor resistance in series, in the ordinary twisted pair transmission hundreds of meters.Ceiling take 20 ma because of explosion-proof requirements: 20 ma electrical current caused by broken spark to ignite the gas energy.Floor did not pick up 0 ma reason is that in order to detect disconnection: normal not less than 4 ma at work, when the transmission line due to the fault circuit, the loop current drop to zero.Often take 2 ma as a disconnection alarm value.

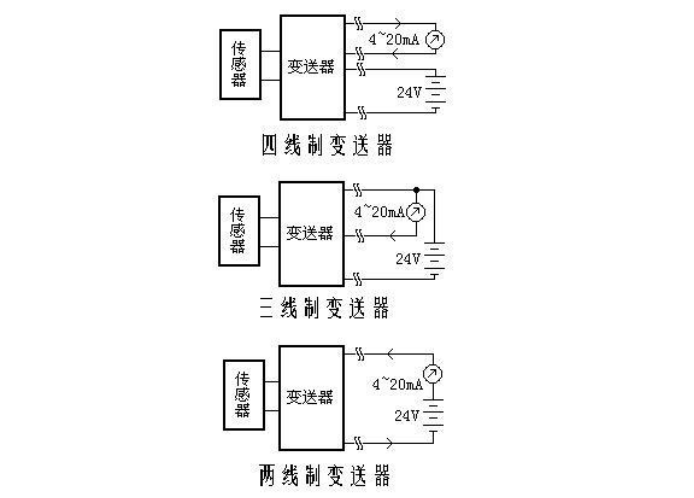

Current output type transducer to convert physical quantities to 4 ~ 20 ma output current, is bound to have external power for the power supply.Transmitter needs is the most typical two power cord, plus two line output current, total want to pick up 4 wires, called four wire transducer.

Of course, a thread can output current and power utilities (public or VCC GND), can save a thread, called three-wire system transmitter.

4-20 ma current itself can actually as the transmitter power supply.Transmitter is equivalent to a special load in the circuit, is special in the transmitter power consumption between 4 ~ 20 ma current according to the sensor output.Display instrument you just need to string in the circuit.The transmitter only external 2 lines, therefore is called the two wire transducer.

In industrial applications, the measurement point generally at the scene, and display devices or control equipment are generally in control room or control on the ark.Distance between the two may dozens to hundreds of meters.According to the one hundred meters distance calculation, save two signal transmission wire means lower costs nearly hundred dollars!The other four wire transducer and three-wire system transmitter because of asymmetric current in the conductor must use expensive shielded wire, and two wire transducer can use very cheap twisted-pair wires, so two wire system in the application of transducer is preferred.

Basic principle of transducer figure two wire system principle and design of current transducer

Twelve, LL - 02 type intelligent flow integrator instructions

1. The main technical indicators

(1) display mode:

Double row liquid crystal display (LCD), as follows:

L XXX. X four instantaneous flow (m3 / h)

XX. XXXXXX eight cumulative flow (m3)

Figure 6

(2) the system low power consumption: section 3.3 V10AH lithium batteries can be used more than 5 years in a row.

(3) the cumulative flow: automatically expand the display precision, the cumulative flow values can be reset.

(4) the meter factor: the scene can be put into.

(5) power-fail protection: instrument coefficient, the cumulative flow values ten years is not lost when power supply drop.

2. Three coefficient double row liquid crystal display, load method (only authorized engineers) :

Open the front cover, press at the same time And F keys, and the instrument enter into the state of load, now ranked the first digital display 1, said at this time can be set up the instrument coefficient of the first point.Four can be set up after the corresponding points on the sensor output pulse frequency value of the instrument coefficient of discharge can be set to eight point value.

And F keys, and the instrument enter into the state of load, now ranked the first digital display 1, said at this time can be set up the instrument coefficient of the first point.Four can be set up after the corresponding points on the sensor output pulse frequency value of the instrument coefficient of discharge can be set to eight point value.

First, highest twinkle, buttons , the bit to add 1 to the required value, press the shift key

, the bit to add 1 to the required value, press the shift key , blinking moves to the right, then use

, blinking moves to the right, then use Key to choose the bit numerical...When flashing displacement to the last, according to

Key to choose the bit numerical...When flashing displacement to the last, according to The key, to put this parameter.Instrument coefficient of format for XXXXXX. XX

The key, to put this parameter.Instrument coefficient of format for XXXXXX. XX

Check after press the F key, can enter the next point meter coefficient setting, setting method, the above format.

Set up after the three coefficients continue to press the F key, the instrument enter into the state of work, show on the four instantaneous flow, discharge display eight total flow.

In working status, press the F key, the total amount can be reset.

Note: using three instrument coefficient of flow sensor nonlinear correction requires the user to know flow sensor and some corresponding meter coefficient (frequency) how much is respectively, namely F1, K1, F2 - K2, F3 -- K3.

3, field display with 4 ~ 20 ma output header

(1) boot show LL - 02.02, said to take 4 ~ 20 ma output, 24 VDC power supply.

(2) full scale flow to 20 ma, with lower flow said small flow resection.

(3) damping coefficient to show the number of + 1 second time sampling again.

(4) open the rear case, terminals, can be seen by the line diagram connected.

(5) any other operation method and the battery meter.

13, maintenance and common fault:

Sensor may produce general fault and eliminating methods are shown in table 3, the maintenance period shall not exceed six months.

Table 3

The serial number | The fault phenomenon | why | Elimination method |

1 | Display of traffic signals and inspection are no display | 1. No plug in, not a given voltage. 2. Display is faulty. | 1. Connect the power supply, according to the requirements for a given voltage. 2. Maintenance display instrument. |

2 | Display instrument of "check" signal but no display of the traffic signal. | 1. The sensor and display the indirect line is wrong, or open circuit, short circuit, such as poor contact failure 2. The amplifier has a fault or damage. 3. The converter (coil) open circuit or short circuit. 4. The impeller jammed.Pipeline without fluid flow or jam. | 1. The comparison chart 4, check the correct wiring and connection quality. 2. Repair or replace the amplifier. 3. Repair or replace the coil. 4. Sensors and pipe cleaning. Open the valve or pump, pipeline cleaning. |

3 | Display instrument working instability;Measurement is not correct. | 1. The actual flow is beyond the scope of instrument measurement or unstable. 2. The meter coefficient K set wrong. 3. Hang impurities such as fiber sensor inside. 4. A bubble in the liquid. 5. By the sensor has the strong electromagnetic interference. 6. The sensor bearing and shaft serious wear and tear. 7. The sensor or other grounding wire and cable shielding layer circuit ground wire broken or poor contact. 8. Display instrument malfunction. | 1. Make the measured flow and sensor measurement range, and steady flow. 2. Make coefficient K is set correctly. 3. Cleaning the sensor. 4. Venting measures to eliminate air bubbles. 5. Far away from disturbance sources as far as possible or shielding measures. 6. Replace the "guide" or "impeller shaft". 7. Control chart, four line will connect well. 8. Maintenance display instrument. |

14, transportation and storage

Sensors should be in strong wooden case (small diameter instrument available cartons), not allowed in the free running in the cabinet, handle with care when handling, do not allow the rough handling.

Location shall meet the following conditions:

Rain moistureproof.

A. is not affected by mechanical vibration or impact.

B. temperature range - 20 ℃ ~ + 55 ℃.

C. relative humidity is not greater than 80%.

D. no corrosive gas in the environment.

15, out of the matters needing attention

1. When unpacking the case, according to the packing list to check the file and accessories are complete.

A packing files are: operation instruction.

A manufacturer's certificate.

Verification certificate.

2. Observe the phenomenon such as sensor for due to transportation damage, in order to properly handle.

3. Looking at the user keep "calibration certificate" do not lose, otherwise unable to set the meter factor!

16 and ordering information

Users should note when ordering turbine flow sensor based on the fluid of nominal diameter, working pressure, working temperature, flow range, fluid types and environmental conditions, choose the appropriate specifications.When have explosion-proof requirements must choose explosion-proof type sensor, and strict attention to explosive-proof grade.

Seventeen, use period

Users abide by the provisions of the manual for storage and use cases, within one year from the delivery of the factory, the sensor can't work normally, the factory can be repaired free of charge.

Mail

Mail Chinese

Chinese English

English