One, the introduction:

LGK series of orifice plate flowmeter is also known as differential pressure flowmeter, consists of a test piece (throttle) and the second device (differential pressure transmitter and flow display) is widely applied in gas. The vapor and liquid flow measurement. It has a simple structure, convenient maintenance, stable performance and reliable use, etc.

Intelligent throttling device (orifice meter) is integrating flow, temperature and pressure detection, temperature, pressure, and can automatically compensate a new generation of flowmeter, the orifice meter adopts the new technology of advanced computer technology and micro power consumption, strong function, compact structure, simple operation, easy to use.

Second, the measuring principle:

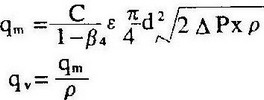

LGK series is full of pipeline fluid orifice plate flowmeter, when they flow through the pipe orifice flow, velocity of flow in the formation of local contraction flow orifice throttling, accelerated to flow, static pressure is reduced, so the standard orifice plate before and after the pressure drop is produced or differential pressure, the greater the flow medium traffic, the flow before and after the orifice of the greater the pressure difference, so can be measured by a pressure difference to measure the size of the fluid flow.This kind of measurement method based on flow continuity equation (conservation of mass) and the Bernoulli equation (energy conservation) based on the principle of.Under the condition of known related parameters, according to the principle of flow continuity and Bernoulli's equation can be deduced the relationship between the pressure and flow rate and flow rate are obtained.The basic formula is as follows:

C - outflow coefficient of dimensionless

D - working conditions or throat diameter of throttle orifice

Upstream pipe diameter D - working conditions

Qm - mass flow Kg/s

Qv - after volume flow m/s

To decide - diameter ratio d/d dimensionless

The density of fluid Kg/m after

Dimensionless expansiveness coefficient

Third, areas of application:

LGK series hole is the standard orifice plate flowmeter with many parameters of the differential pressure transmitter (or differential pressure transmitter, temperature transmitter and pressure transmitter) form a complete set of high contrast range pressure flow device, can measure the rate of flow of gas, steam, liquid and gas, widely used in petroleum, chemical industry, metallurgy, electricity, heating, water supply in areas such as process control and measurement.

Four, the structure of the orifice meter:

The throttle device of

Throttling: standard orifice, nozzle, 1/4 round hole length to diameter nozzle, plate, double orifice, eccentric orifice, segmental orifice, conical inlet orifice plate, etc

Take pressure device: ring room, take pressure flanges, clamping ring, pressure pipe, etc

Connecting flange (national standard flange, all kinds of standard and other design department), fasteners.

The measuring tube.

Five, the structure of the orifice plate flowmeter classification:

1, annulus pressure standard orifice:

The standard orifice plate.Due to implement the annulus pressure, improves the measuring accuracy, shortens the installation time required minimum straight section length and can be widely used in each department.

2, Angle joint single borehole pressure standard orifice:

The standard orifice plate.When more than 400 mm in diameter, with this form.Take pressure method for flange single borehole pressure, circular equalizing ring or square take pressure equalizing ring.Orifice form can provide with handle holes or non-standard segmental orifice plate, etc.

3, flange pressure standard orifice:

The standard orifice plate.Upstream or downstream regardless of pipe diameter size, its take pressure hole center, located on both sides of the orifice plate face one (25.5 mm), each of the various refining system widely used this form.

4, diameter pressure standard orifice:

The standard orifice plate.Take pressure method for pipeline pressure.Take pressure upstream hole center is located in the front of the orifice pipe diameter.Take pressure hole center is located in the downstream distance orifice and a half after the end of pipe diameter.

5, small-bore orifice:

The standard orifice plate.Used to measure fluid within 10 mm to 50 mm diameter measurement.

6, double orifice:

Is the distance from each other in a certain installed on the straight pipe of the two pieces of standard orifice plate.According to the flow direction of the beam, the hole in front of the said is complementary orifice plate, the back of the orifice said orifice.Auxiliary orifice cross-section than m1 is greater than the main section of orifice than m.Two pieces of orifice plate makes the walls of a similar liquid nozzle.It is used for low Reynolds number or high viscosity fluid flow measurement.

7, segmental orifice:

Belong to non standard orifice, be applicable to the dirt, or have a bubble analysis, or contains solid particles in the measurement of fluid flow and its measurement precision is low.

8, conical inlet orifice:

The standard orifice plate.Circular cone with the center line of the Angle is 45 °, the conical inlet orifice can suitable for occasions with low Reynolds number, but shall not be less than 25 mm pipe size.Six, orifice plate flowmeter key features:

1, the throttle device structure easy to copy, simple, firm, stable and reliable performance, long service life, low price.

2, orifice calculation adopt international standards and processing.

All three, wide application range, single phase flow are measured, partially miscible flow can also be applied.

4, standard throttle device without real flow calibration, putting-in-service proactively.

5, a body orifice plate installation is more simple, do not need to bring pressure pipe, can be directly answering the differential pressure transmitter and pressure transmitter.

Seven, orifice plate flowmeter technology parameters:

CAL: DN25 ~ DN1000 (mm);

Accuracy: + / - 1% FS.

Range than: standard 1:13, expanding 1:30;

Working pressure: 42.0 MPa or less;

Medium temperature: - 40 c ~ 450 c;

Medium viscosity: 30 or less cp (crude oil);

Beta: 0.2 ~ 0.8;

Connection mode: flange or clamp type;

The flange standard:

DN≤600mm, PN2.0~PN26,HG20616;PN32,HG20618;

DN>600mm,PN2.0~PN15,HG20623;

Can also be made according to standard provided by the user flange;

Material: subject, orifice plate, pressure pipe, three valve group: stainless steel;Straight pipe and the connecting flange: carbon steel or stainless steel;

Installation method: horizontal or vertical;

Smart differential pressure transmitter: output: 4 ~ 20 ma. DC or digital signal;Power: 24 v DC;

Explosion-proof grade: d Ⅱ CT5.6, ia Ⅱ CT4-6;Protection grade: IP67;

Header: blind table and digital display table two.

Eight, the debugging method:

1, signal lines, the power cord

2 valve, open the import and export, import and export valve opening

3, open the three stainless steel valve group balancing valve, slowly open the orifice to the high and low pressure valves, stay fluid through the flowmeter balancing valve can be closed after three stainless steel valve group.

Nine, the maintenance of the orifice plate flowmeter installation pipeline conditions:

1, the straight pipe before and after the throttle articles must be straight, bend shall not be visible to the naked eye.

2, install throttle with straight pipe should be smooth, if not smooth, flow coefficient should be multiplied by the roughness correction sparse.

3, in order to ensure the flow of the fluid in the formation of throttling a 1 d before the full development of the turbulent velocity distribution, and makes the distribution into uniform axisymmetric shape, so

1) straight pipe must be round and throttling range 2 d before, its roundness, its very strict and have certain roundness index.Specific measures:

OD before throttling (A) A, D / 2 D, 2 d4 on the vertical pipe section, by A large distance at least equal to the Angle of the measured four pipe diameter single measurements, the average D.Any diameter single measured value and the difference between the average shall not exceed + / - 0.3%

(B) after the throttle piece, the OD and 2 D location using the above method obtained eight diameter single measurement value of arbitrary single measurement values compared with D, the maximum deviation shall not be more than + / - 2%

2) throttling requires a enough long straight pipe before and after the long enough straight pipe and throttle and diameter on the local resistance of a form before than beta.

3) throttling pieces of upstream side first resistance and the resistance between the straight pipe length according to the form of a second resistance and beta = 0.7 (no matter what is the actual beta) select listed number 1/2

4) throttling upstream side for open space or a diameter of 2 d large container, or open space or a large container with throttling a long straight tube shall not be less than 30 d (d).If throttling and open space or there are other local resistance between large container, except in throttling and local resistance parts with adhesion between specified minimum straight long 1, from the open space to the throttling parts between the straight pipe section chief, also should not be less than 30 d (d).Ten, scope of application:

| Throttling a name | Apply pipe (DN) mm | Suitable diameter than B (d/d) | Application characteristics | The flow coefficient of the uncertainty of Ec % | Design criteria | ||

| Angle of access standard orifice plate | Ring chamber type | 50-50050-500 | 0.2-0.750.2-0.75 | Apply to clean medium of GD structure is suitable for the measurement under the condition of high temperature and high pressure flow | 0.6 to 0.75% | ISO5167GB/T2624-93 | |

| The clamping ring type | 50-500. | 0.2 to 0.75 | Easy to remove dirt, and can be used to clean fluid flow measurement | ||||

| Oblique hole type | 450-1000 (3000). | 0.2 to 0.75 | |||||

| Flange pressure standard orifice plate | 50-1000. | 0.2 to 0.75 | Easy to remove dirt, and are suitable for all kinds of media | 0.6 to 0.75% | ISO5167GB/T2624-93 | ||

| Span with standard orifice plate | 50-1000. | 0.2 to 0.75 | |||||

| Angle of access standard nozzle (ISA1932 nozzle) | 50-500. | 0.3 to 0.8 | Small pressure loss, long life, especially suitable for steam flow measurement | 0.8 to 1.2% | ISO5167GB/T2624-93 | ||

| The length to diameter nozzle | 50-630. | 0.2 to 0.8 | Small pressure loss of long service life, LGP type suitable for high length to diameter nozzle component parameters of water and steam flow measurement | 2.0% | ISO5167GB/T2624-93 | ||

| Classic venturi tube | Mechanical processing type | 100-100. | 0.2 to 0.8 | The pressure loss is small, straight pipe required less than orifice, nozzle | 1.0% | ISO5167GB/T2624-93 | |

| Coarse soldering iron plate type | 200-1200 (2000). | 0.4 to 0.7 | 1.5% | ||||

| Venturi nozzle | 65-65. | 0.316 to 0.77 | Same as above | 1.2 to 1.75% | ISO5167GB/T2624-93 | ||

| A quarter circle orifice | 25-150. | 0.245 to 0.6 | Suitable for low Reynolds number | 2.0 to 2.5% | DIN BS | ||

| Conical inlet orifice | 25-250. | 0.1 to 0.316 | Same as above | 2.0% | BS | ||

| Segmental orifice | 50-1500. | 0.32 to 0.8 | Apply to the smudges, there are air bubbles or containing solid particles flow measurement. | 1.5% | DIN | ||

| The eccentric orifice plate | 100-100. | 0.46 to 0.84 | 1-2% | ASME | |||

| Small hole plate | 12.5-40 | 0.2 to 0.75 | Applicable to small pipe flow measurement | 0.75% | ASME | ||

| The lens type orifice | 12.5-150 | 0.2 to 0.75 | Suitable for high pressure temperature small pipe flow measurement | 0.6 to 0.75% | ISO5167ASME | ||

Eleven, technical indicators:

| The name of the | model | Take pressure way | Nominal diameter (mm) | Nominal pressure (MPa) | Execution standard (structure) |

The standard orifice plate | LGB | Pressure Angle joint (annulus) | 50 ~ 400 | Less than 10 | GB2624K07 LanHua DG |

| LGB-Z | Pressure Angle joint (drilling) | 400 ~ 2000 | Less than 1.6 | ||

| LGB | Ring chamber (8 slot) | 50 ~ 400 | Less than 32 | The flow measurement manual | |

| LGB | Ring room (no flange welded) | 50 ~ 275 | Less than 28.22 | The flow measurement manual DG0711 ~ 0718 | |

| LGB-F | The flange to take pressure | 50 ~ 800 | Less than 2.5 | GB2624K06 (LanHua) | |

| LGB-F | The flange to take pressure | 50 ~ 400 | 4.0 ~ 40 | GB2624K06 (LanHua) petrochemical | |

| LGB-J | Span to take pressure | 50 ~ 760 | Less than 10 | GB2624 | |

Standard nozzle | LGP | Pressure Angle joint (annulus) | 50 ~ 400 | Less than 10 | Manual GB2624 flow measurement |

| LGP-Z | Pressure Angle joint (drilling) | 400 ~ 500 | Less than 1.6 | ||

| LGP | Ring chamber (8 slot) | 50 ~ 300 | Less than 32 | The flow measurement manual | |

| LGP | Ring room (high pressure lens pad) | 15-150 | Less than 32 | ||

| LGP | Ring room (no flange welded) | 175 ~ 350 | Less than 17.36 | DG 0702~0710 | |

| Length to diameter nozzle | LGC-J | Span to take pressure | 50 ~ 630 | Less than 16 | GB2624 |

| A quarter circle orifice | LGH | Take pressure Angle joint | 50 ~ 260 | Less than 10 | Manual GB2624 flow measurement |

| LGH-F | The flange to take pressure | 50 ~ 200 | Less than 6.4 | ||

| Venturi nozzle | LGL | Take pressure Angle joint | 65 ~ 500 | Less than 2.5 | |

| Venturi tube | LGW | Take special pressure | 50 ~ 1200 | Less than 2.5 | |

| Double venturi tube | LGW-S | Take special pressure | Less than 1000 | Less than 0.6 | |

| Small diameter orifice | LGX | Take pressure Angle joint | 12 ~ 40 | Less than 6.4 | K07 (LanHua) |

| LGX-F | The flange to take pressure | 12 ~ 40 | Less than 6.4 | The enterprise standard | |

| High pressure lens gasket | LGT | Take pressure Angle joint | 50 ~ 150 | Less than 32 | The flow measurement manual |

Segmental orifice | LGQ | Pressure Angle joint (annulus) | 100 ~ 400 | Less than 1.6 | |

| LGQ-Z | Pressure Angle joint (drilling) | 400 ~ 1000 | Less than 1.6 | ||

| LGQ-F | The flange to take pressure | 100 ~ 350 | Less than 6.4 | ||

| Double orifice | LGS | Take pressure Angle joint | 100 ~ 400 | Less than 6.4 | |

| The eccentric orifice plate | LGN | Take pressure Angle joint | 100 ~ 1000 | Less than 6.4 | |

| Throttling orifice plate | LG-XL | 10 to 300 | Less than 6.4 | The enterprise standard | |

| Conical inlet orifice | LGR | Take pressure Angle joint | 25 ~ 1000 | Less than 10 | GB2624 |

| The wing wind device | LJY | Take special pressure | Less than 1000 | Less than 0.6 | The enterprise standard |

Twelve, orifice plate flowmeter selection table:

model | Said Ming | |||||||||

| LG | The throttle device | |||||||||

| Code name | According to the structure characteristics of the two basic categories | |||||||||

| K | Orifice plate | |||||||||

| P | Nozzle etc. | |||||||||

Code name | Nominal pressure (105 pa) | |||||||||

2.5 | 2.5 | |||||||||

10 | 10 | |||||||||

16 | 16 | |||||||||

25 | 25 | |||||||||

64 | 64 | |||||||||

100 | 100 | |||||||||

200 | 200 | |||||||||

Code name | Diameter (mm) | |||||||||

| 10 to 1600 | 10~1600mm | |||||||||

Code name | According to its structure form of segmentation | |||||||||

H | Standard orifice (annulus) | |||||||||

Y | Standard orifice (flange) | |||||||||

K | Standard orifice (drilling) | |||||||||

I | ISA 1932 nozzle | |||||||||

L | The length to diameter nozzle | |||||||||

W | Venturi nozzle | |||||||||

G | Classic venturi tube | |||||||||

S | Double orifice | |||||||||

Q | Segmental orifice | |||||||||

Z | Conical inlet orifice | |||||||||

R | A quarter circle orifice | |||||||||

P | The eccentric orifice plate | |||||||||

N | As a whole (hidden) orifice | |||||||||

X | Wedge orifice | |||||||||

T | Out of place in the above special throttling device | |||||||||

Code name | medium | |||||||||

1 | liquid | |||||||||

2 | gas | |||||||||

3 | steam | |||||||||

4 | High temperature liquid | |||||||||

Code name | Compensation in the form of | |||||||||

N | Without pressure and temperature compensation | |||||||||

P | With pressure compensation output | |||||||||

T | With temperature compensation output | |||||||||

Q | With compensation output pressure and temperature | |||||||||

Code name | Differential pressure transmitter range scope | |||||||||

0 | Micro differential pressure range | |||||||||

1 | Low differential pressure range | |||||||||

2 | The differential pressure range | |||||||||

3 | Elevation difference pressure range | |||||||||

Code name | Whether or not to bring a live show | |||||||||

W | The throttle device sensors | |||||||||

X | Intelligent throttling device (meter) | |||||||||

Code name | The power supply mode | |||||||||

0 | External + 24 VDC power supply | |||||||||

1 | 3.6 V batteries | |||||||||

13 order, design notes:

Orifice plate flow timing users order please provide the following conditions in order to help the correct choice of the specifications of the flowmeter and coefficient.

1, pipe size: diameter x wall thickness (mm);

2, measuring medium name: medium density (kg/m3);

3, set the maximum flow: meter on the range of limit (kg/h or m3 / h);

4, process of minimum flow: (kg/h or m3 / h);

5, work pressure (Mpa);

6, work temperature: (° C);

7, such as wei in match together, please provide: intelligent flow totalizer.especially pressure range, or pressure transmitter type, range;Temperature range, or models, range temperature transmitter.

Mail

Mail Chinese

Chinese English

English